Types of CO2 Extraction:

The entire CO2 extraction is labeled in two types.

The first one is Low pressure cold extraction. Under this process, the Co2 is allowed to chill between 35 to 55 degrees F and through the plant material, the it involves pumping at a rate ranging from 800 psi to 1500 psi. This process is often considered to be the best method for production of high quality botanical extractions. At this state, CO2 has a high loading rate, which indicates that you will have to pump several volumes of CO2 through a given volume of botanical slot. The loading rate is typically of 10 to 40 volumes.

The second process of CO2 Extraction is Supercritical Fluid Extraction. This process is involved in the heating of CO2 with a temperature that is more than 87degree F and is allowed to pump above 1100 psi. This process has a advantageous feature that it can possess faster loading rate ranging from 2 to 10 volumes and also has a wide range of uses. On the other hand, one of its major drawback is that some of the extractions done can get damaged either by the high pressure breaking molecular ring structures or the fact that moisture present in the process can react with the CO2 and hence form carbonic acid which turns some oils rancid, thus not working effectively.

Process:

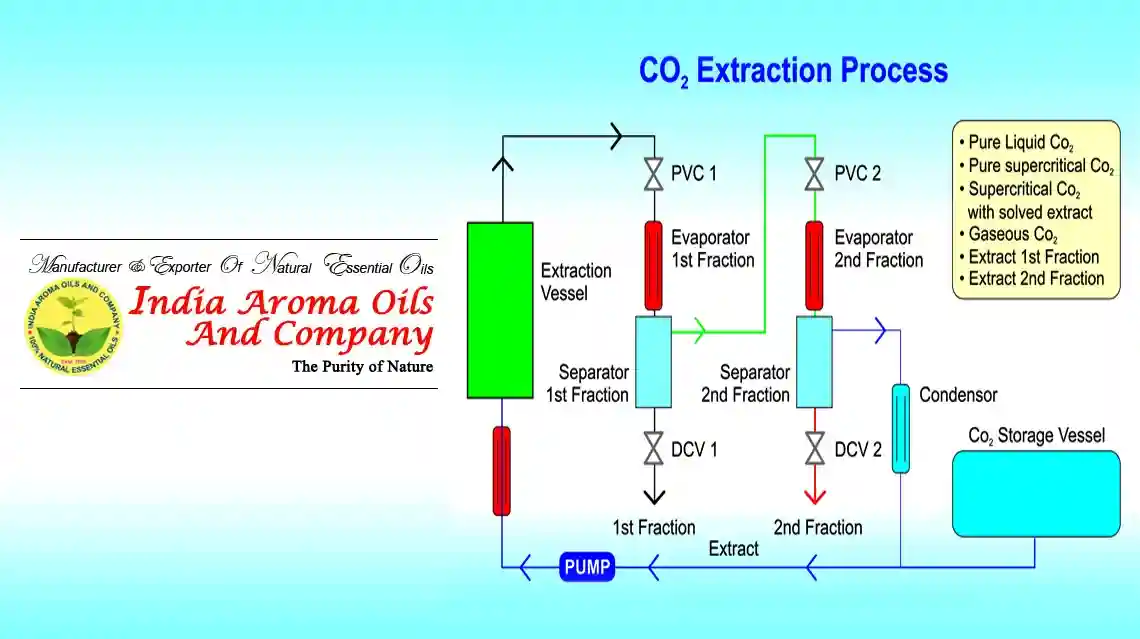

The highly and advanced technical process of Supercritical Fluid extraction or liquid CO2 is designed by taking in account the heavy apparatus. The extraction vessel, evaporator, separator, pump, condenser and storage vessel all work together to make the process simplified. The plant material is then stuffed in a pressure vessel. Then the further pumping is done on the liquified CO2 gas or liquid solvent, and it is carried out at a specific pressure and temperature which is also called the critical point. The pressure so formed forces the solvent into the wall of the cells of the botanical and separates the desired constituent rapidly. The fluid then obtained from CO2 enhances the solvent's characteristics.

Applications:

The applications of the Co2 extraction process are:

- In the Coffee industry to minimize caffeine

- In the Biomedical industries to sterilize tools and equipments

- The method is used extensively in thermoplastic or fired ceramics