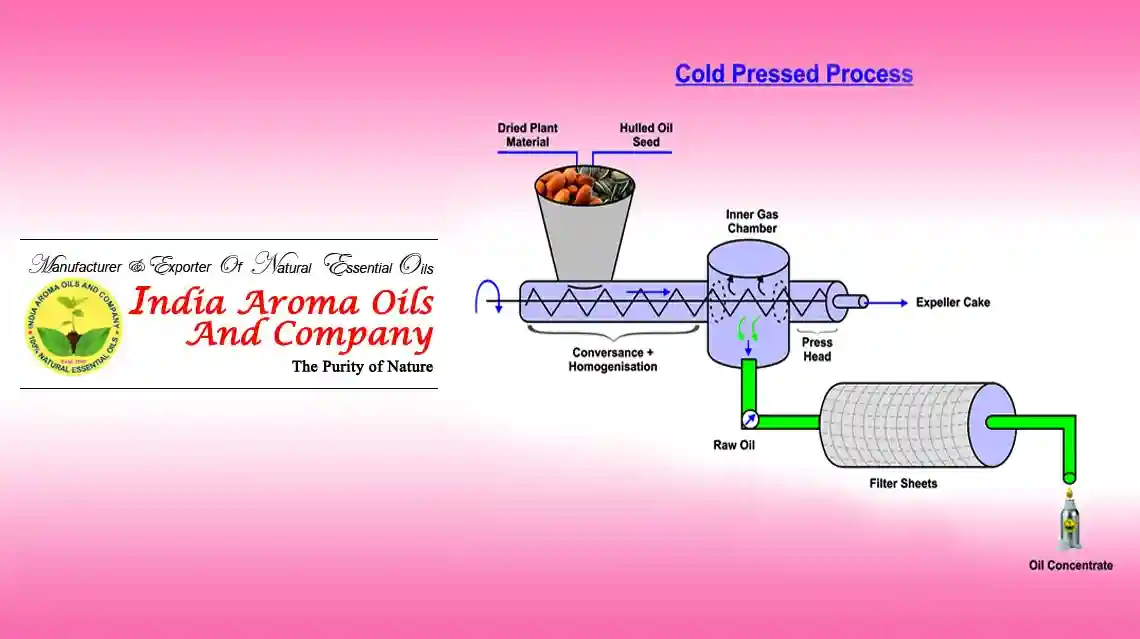

Working process:

In the cold pressed process, firstly the shell of the fruits are drilled by rolling them over a trough. Doing this, sacks filled with the essential oils are easily pierced and juiced out. Further ahead, the entire fruit is pressured to squeeze the essential oils and the juices from the pulp leaving behind no more oil left in the remaining part. The separation method that follow it, is done from the juice and oil obtained by the help of centrifugation process. The indispensable juice and oils produced out from the process expires in a very short span of time.

History of cold-pressed:

The term 'Cold-pressed' is imitated from the German words 'kalt geschlagen', which hereby means 'cold pummeled'. In Switzerland, 'cold-pressed' is also defined as to mean that the oils and the juices have not reached the temperatures that could possibly exceed 50°C in the entire making of it. Under this process, no external heat is fueled to the oils and despite of that, the heat is produced in a very high temperature during its deodorization. This itself confirm the fact that there is no sort of external heat omitted out in this entire modern process. The heat that is produced is generally because of the pressure resting inside and also because of rotational friction. In a rough estimate, in Germany, 100 years ago, the oils and the juices were prepared by the women themselves in a manual manner. The process was like poring the seeds into a wedge-shaped container and a wooden edge was inserted into it. Those housewives then used to hit the wedge with a wooden mallet and the oil would drip out of the raw materials for about an hour. This process was continued and repeated after every hour and the temperature of the dripping oil ranged from 85 and 95°C.

Applications:

This Cold pressed method is chiefly used for the extracting of the most essential oils from their plant ores, their seeds and the fruits. This method is also used to plunge out citrus fruit oils such as Bergamot, Grapefruit, Lemon, Lime, Mandarin, Orange and Tangerine oils.